-

Our Products

- Static Mixer

- Chemical Storage Tank

- FRP Vessel

- FRP Tank

- Degassing System

- Self Cleaning Filters

- Cartridge Filter Housings

- Gas Scrubber

- Industrial Strainer

- PP Tanks

- Cartridge Filter

- Air Blowers

- FRP Mixed Bed vessel

- Pickling Tank

- GRP Tanks

- Micron Filter

- FRP Damper

- Activated Carbon Filter

- Industrial Equipments

- Industrial Filters

- Degasser Column

- Demineralisation Plants

- Pressure Sand Filter

- FRP Centrifugal Fans

- Absorption Tower

- Industrial Reactors

- RO Plant

- Fume Exhaust Blower

- Water Softener Plant

- Home Page

- Company Profile

- Infrastructure

- Contact Us

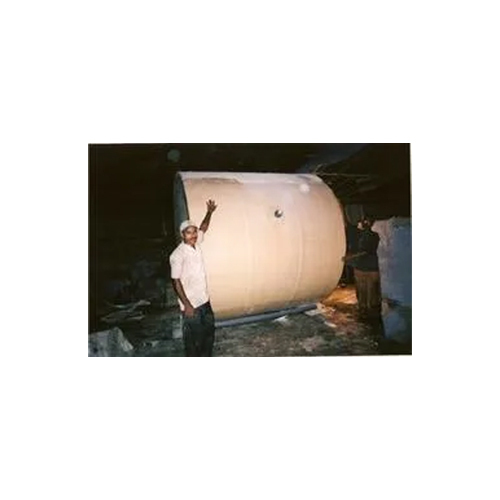

Vertical FRP Tank

100000.00 INR/Piece

Product Details:

- Material Fiberglass Reinforced Plastic

- Shape Vertical Cylindrical

- Application Industrial Liquid Storage, Chemical Storage, Water Storage

- Click to view more

X

Vertical FRP Tank Price And Quantity

- 100000.00 INR/Piece

- 1 Piece

- 100000.00 - 1000000.00 INR/Piece

- Available as per Chemical Compatibility

- Low

- -40°C to +120°C

- Easy to Install, Lightweight Design

- Up to 10 meters or as required

- Grey / Customized

- Vertical Standing

- High

- 100% Leak Proof Construction

- Top & Side Nozzle Connections (As Per Client Requirement)

- Excellent

- 5 mm to 24 mm (Depending on Capacity)

- 500 mm to 4000 mm (Standard Options)

Vertical FRP Tank Product Specifications

- Fiberglass Reinforced Plastic

- Industrial Liquid Storage, Chemical Storage, Water Storage

- Vertical Cylindrical

- Available as per Chemical Compatibility

- Low

- -40°C to +120°C

- Easy to Install, Lightweight Design

- Up to 10 meters or as required

- Grey / Customized

- Vertical Standing

- High

- 100% Leak Proof Construction

- Top & Side Nozzle Connections (As Per Client Requirement)

- Excellent

- 5 mm to 24 mm (Depending on Capacity)

- 500 mm to 4000 mm (Standard Options)

Vertical FRP Tank Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1 Piece Per Week

- 1-2 Week

- All India

Product Description

With an aim to achieve a commendable position in the market, we are successfully engaged in providing the best quality array of Vertical FRP Tank. This tank find its important application in pharmaceutical, chemical processing, paper making and food processing industries for safe storage of chemicals. Our ingenious professionals manufacture this tank using the best grade fiber reinforced plastics and the progressive techniques. To assure its flawlessness, the provided Vertical Fibre-reinforced plastic Tank is tested on defined parameters of quality by our experts.

Features of Vertical FRP Tank:

- Robust design

- Withstand high temperature

- Leakage proof

- Impact resistance

Testing Facilities:

- Spark tester

- Hardness tester

- Hydro tester

- Tensile testing machine

- Applicable industries:

- Chemical process industry

- Metal refining industry

- Pharmaceutical industry

- Food processing industry

- Pulp and paper industry

- Metal finishing industry

- Fertilizer industry

- Desalination plants

- Water treatment plants

Specifications:

- Capacity: 1 KL to 300 KL

- Temperature: 20 ºC-110 ºC

- MOC: PP / FRP / PVC / PVDF / FRVE

Vertical FRP Tank Details:

| Type | Vertical / Horizontal / Cylindrical / Rectangular |

| Capacity | 1 KL to 300 KL |

| Temperature | 20 Degree C -110 Degree C |

| Pressure | Atmospheric / Vacuum / Pressurized |

| Material Of Construction | Fiberglass Reinforced Plastic |

| LIFTING ARRANGEMENT | Lifting Hook On Tank |

| HOLDING ARRANGEMENT | Lugs |

| Color | Grey, Black, Blue |

Exceptional Chemical & Corrosion Resistance

Engineered for demanding environments, these vertical FRP tanks deliver excellent resistance against a variety of chemicals and corrosion. Their adaptive inside lining ensures safe containment for even aggressive substances, making them a preferred choice for industrial and chemical applications. Longevity and reliability are prioritized in every unit.

Customizable Dimensions & Connections

Offering flexibility in diameter, height, wall thickness, and color, these tanks are tailored to specific site and process requirements. Top and side nozzle connections are fitted as per client needs, ensuring efficient compatibility with existing infrastructure and processes.

Effortless Installation and Maintenance

Lightweight and structurally robust, these vertical tanks facilitate quick and hassle-free installation and require minimal maintenance. Their leak-proof construction and high UV resistance minimize operational downtime and maximize operational safety, making them a cost-effective choice over conventional tanks.

FAQs of Vertical FRP Tank:

Q: How is the vertical FRP tank installed on-site?

A: The vertical FRP tanks lightweight design and pre-configured nozzle connections allow it to be easily positioned and installed with standard lifting equipment. Installation typically involves securing the tank on a prepared foundation and connecting inlet/outlet nozzles as per client requirement.Q: What chemical compatibility options are available for the tank lining?

A: Inside linings can be customized based on the specific chemical to be stored. During the order process, clients provide details on the chemicals, and the manufacturer recommends and applies the optimal lining for safe and long-term storage.Q: When should I choose a customized color or dimension for my FRP tank?

A: Customized colors or dimensions are ideal when specific visual identification, branding, or precise fit within site constraints is required. Providing these preferences during the ordering stage ensures the tank meets unique operational and aesthetic needs.Q: Where can these vertical FRP tanks be used effectively?

A: These tanks are most effective in applications such as industrial liquid storage, chemical storage, and water storage. Common installation sites include manufacturing plants, chemical processing units, water treatment facilities, and various industrial settings across India and abroad.Q: What is the process for ordering a tank with specific connections and capacity?

A: Clients specify the required diameter, height, wall thickness, nozzle locations, and color during the inquiry. The manufacturer then designs and fabricates the tank accordingly, ensuring all features are tailored to the users operational requirements.Q: What are the main benefits of choosing an FRP tank over traditional storage solutions?

A: FRP tanks provide superior corrosion and UV resistance, are 100% leak-proof, lightweight, and demand low maintenance. These advantages significantly reduce operational costs and extend the tanks service life, especially in harsh environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free