-

Our Products

- Static Mixer

- Chemical Storage Tank

- FRP Vessel

- FRP Tank

- Degassing System

- Self Cleaning Filters

- Cartridge Filter Housings

- Gas Scrubber

- Industrial Strainer

- PP Tanks

- Cartridge Filter

- Air Blowers

- FRP Mixed Bed vessel

- Pickling Tank

- GRP Tanks

- Micron Filter

- FRP Damper

- Activated Carbon Filter

- Industrial Equipments

- Industrial Filters

- Degasser Column

- Demineralisation Plants

- Pressure Sand Filter

- FRP Centrifugal Fans

- Absorption Tower

- Industrial Reactors

- RO Plant

- Fume Exhaust Blower

- Water Softener Plant

- Home Page

- Company Profile

- Infrastructure

- Contact Us

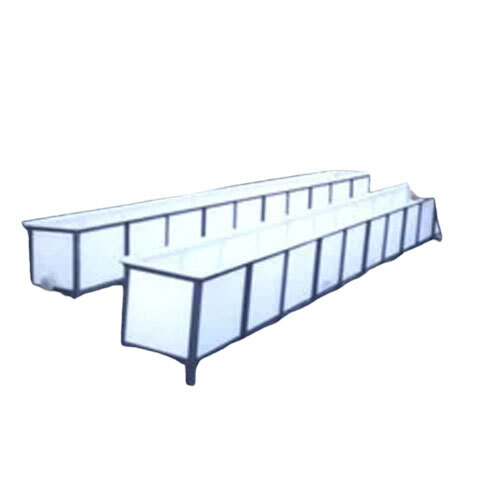

Rectangular FRP Tanks

60000 INR/Piece

Product Details:

- Material Fiberglass Reinforced Plastic

- Capacity 1 KL to 300 KL Kiloliter/day

- Shape Rectangular

- Application Industrial storage of chemicals, water, effluent, acids, pharmaceutical and food-process containment

- Click to view more

X

Rectangular FRP Tanks Price And Quantity

- 60000 INR/Piece

- 10000.00 - 25000.00 INR/Piece

- 1 Piece

- Glass fiber mat and resin

- More than 10 years under recommended conditions

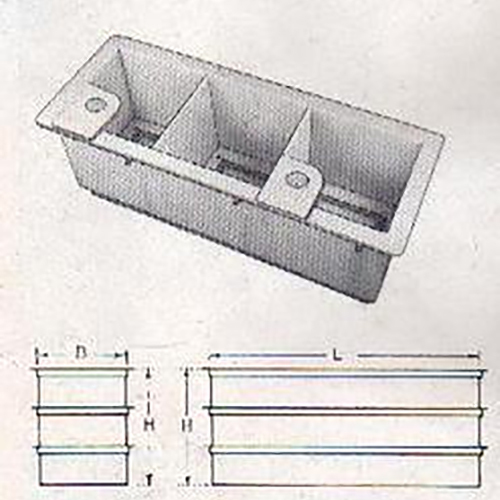

- Flanged/coupling inlet, outlet, manhole, level indicators and optional partitions

- 5 mm to 25 mm (customizable as per capacity and design)

- Light Grey or as per customer requirement

- Yes, monolithic molded structure

- Smooth, glossy, non-porous finish

- -40°C to 120°C (depending on resin type)

- High resistance to most chemicals and corrosive agents

Rectangular FRP Tanks Product Specifications

- Rectangular

- Fiberglass Reinforced Plastic

- 1 KL to 300 KL Kiloliter/day

- Industrial storage of chemicals, water, effluent, acids, pharmaceutical and food-process containment

- Glass fiber mat and resin

- More than 10 years under recommended conditions

- Flanged/coupling inlet, outlet, manhole, level indicators and optional partitions

- 5 mm to 25 mm (customizable as per capacity and design)

- Light Grey or as per customer requirement

- Yes, monolithic molded structure

- Smooth, glossy, non-porous finish

- -40°C to 120°C (depending on resin type)

- High resistance to most chemicals and corrosive agents

Rectangular FRP Tanks Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 1 Piece Per Week

- 1-2 Week

- All India

Product Description

We are a pronounced manufacturer, exporter and supplier of optimum quality array of Rectangular FRP Tanks. Our diligent professionals manufacture these tanks as per set industry standards using optimum grade fiber reinforced plastic at our advanced production unit. Ideally used in several chemical, food processing and pharmaceutical industries, the offered tanks are made available in different capacities as per the requirements of our clients. In addition to this, our clients can easily purchase the provided Rectangular FRP Tanks at reasonable prices from us.

Features of Rectangular FRP Tanks:

- Robust construction

- Impact resistance

- Non corrosive surface

- High strength

Testing facilities:

- Spark tester

- Hardness tester

- Hydro tester

- Tensile testing machine

Applicable industries:

- Chemical process industry

- Pharmaceutical industry

- Food processing industry

- Metal refining industry

- Pulp and paper industry

- Metal finishing industry

- Fertilizer industry

- Desalination plants

- Water treatment plants

Specifications:

- Capacity: 1 KL to 00 KL

- Temperature: 20 -110

- MOC: PP / FRP / PVC / PVDF / FRVE

- Type: Vertical / Horizontal / Cylindrical / Rectangular

- Pressure: Atmospheric / Vacuum / Pressurized

Product Details:

|

Temperature |

20 Degree C -110 Degree C |

|

Type |

Horizontal |

|

Material Of Construction |

Fiberglass Reinforced Plastic |

|

Pressure |

Atmospheric / Vacuum Pressurized |

|

Storage Capacity |

2000L, 1500L, 1000L |

|

Shape |

Rectangular |

|

Capacity |

1 KL to 300 KL |

|

Brand |

DM |

|

Color |

Blue |

Durable Construction and Design

Rectangular FRP Tanks utilize a monolithic molded structure, reinforced with glass fiber mat and quality resin. The customizable thickness ensures optimal strength, meeting capacity and design needs from 1 KL to 300 KL. The smooth, non-porous finish not only enhances visual appeal but also simplifies cleaning and maintenance, making these tanks suitable for demanding industrial and commercial environments.

Excellent Chemical and Corrosion Resistance

These tanks are engineered for superior resistance to most chemicals and corrosive agents, making them ideal for storing aggressive liquids and chemicals. The fiberglass-reinforced plastic material, combined with advanced resin systems, guarantees a long service life and durability, even in harsh operating conditions. This resilience translates directly into long-term savings and reliability.

Customizable Features and Accessories

Each FRP tank can be tailored with color choices, wall thickness, and a range of fittings including flanged or coupling inlets and outlets, manholes, level indicators, and optional internal partitions. This flexibility allows manufacturers, exporters, and suppliers in India to meet diverse project specifications, enhancing operational efficiency and convenience for end users.

FAQs of Rectangular FRP Tanks:

Q: How can customers customize the color and wall thickness of Rectangular FRP Tanks?

A: Customers can select between the standard light grey or request custom colors. Wall thickness is also adjustable from 5 mm to 25 mm based on the required capacity and design, ensuring the tank meets specific mechanical and chemical storage requirements.Q: What applications are recommended for these FRP tanks in India?

A: These tanks are suitable for industrial chemical storage, water treatment plants, and other sectors requiring high corrosion resistance and leak-proof storage. Their robust construction and customizable features make them adaptable to various processes in manufacturing, exporting, and supplying roles.Q: When should optional fittings and accessories be considered?

A: Optional fittings such as flanged/coupling inlets and outlets, manholes, level indicators, and internal partitions should be considered during tank selection to enhance operational flexibility and monitoring. Choosing these accessories ensures efficient and safe management depending on the applications operational needs.Q: Where are Rectangular FRP Tanks manufactured and supplied from?

A: These tanks are manufactured, exported, and supplied in India, providing reliable solutions to domestic and international customers who require corrosion-resistant and customizable storage options.Q: What benefits does the smooth, glossy, non-porous surface of the tank provide?

A: The smooth, glossy, non-porous finish minimizes residue buildup, simplifies cleaning, and prevents contamination. This surface quality is especially beneficial for industries requiring strict hygiene and low maintenance operations.Q: How does the reinforced structure contribute to the tanks performance?

A: The use of glass fiber mat and resin in reinforcement ensures high structural integrity and durability. This monolithic design allows the tank to maintain leak-proof performance and resist deformation under pressure, enhancing long-term reliability.Q: What service life can customers expect from these FRP tanks, and what conditions optimize longevity?

A: Under recommended operating conditions, these FRP tanks deliver more than 10 years of service life. Longevity is optimized by selecting suitable resin types, routine cleaning, and choosing appropriate wall thickness for specific chemical and temperature exposures.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free