-

Our Products

- Static Mixer

- Chemical Storage Tank

- FRP Vessel

- FRP Tank

- Degassing System

- Self Cleaning Filters

- Cartridge Filter Housings

- Gas Scrubber

- Industrial Strainer

- PP Tanks

- Cartridge Filter

- Air Blowers

- FRP Mixed Bed vessel

- Pickling Tank

- GRP Tanks

- Micron Filter

- FRP Damper

- Activated Carbon Filter

- Industrial Equipments

- Industrial Filters

- Degasser Column

- Demineralisation Plants

- Pressure Sand Filter

- FRP Centrifugal Fans

- Absorption Tower

- Industrial Reactors

- RO Plant

- Fume Exhaust Blower

- Water Softener Plant

- Home Page

- Company Profile

- Infrastructure

- Contact Us

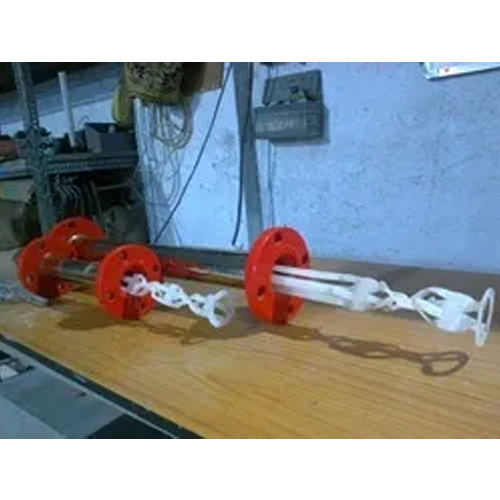

PTFE Static Mixers

10000.00 - 100000.00 INR/Unit

Product Details:

- Type Static Mixers

- Material Polytetrafluoroethylene

- Computerized No

- Automatic Grade Manual

- Warranty Yes

- Click to view more

X

PTFE Static Mixers Price And Quantity

- 1 Unit

- 10000.00 - 100000.00 INR/Unit

PTFE Static Mixers Product Specifications

- Polytetrafluoroethylene

- Static Mixers

- Manual

- Yes

- No

PTFE Static Mixers Trade Information

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 10 Unit Per Day

- 1-2 Week

- All India

Product Description

With an aim of achieving clients satisfaction, we are indulged in manufacturing, exporting and supplying optimum quality PTFE Static Mixers. Our dexterous professionals manufacture these mixers by utilizing optimum quality polytetrafluroethylene at our advanced production unit equipped with the latest technology and cutting edge machines. Finding usage in high temperature and aggressive chemical mixing applications, the provided mixers are also tested on several quality aspects. Moreover, we provide these Polytetrafluoroethylene Static Mixers at reasonable prices to the clients.PTFE (Polytetrafluoroethylene) Static Mixers Features: Highly efficient mixing Low energy consumption No need for tanks in most cases Ease of installation Minimal space requirement Totally enclosed pipe designs Optional injectors and sample points Available in all sizes Available in a wide range of materials No moving parts for maintenance free operation Applications of Polytetrafluoroethylene Static Mixers: Water and waste water Aerating water for FE and MN removal Energy Mixing blast furnace and coke oven gas Blending fuel gases with air before combustion Polymers Mixing additives, catalysts, into polymers Rapid heating of polymers Homogenization of temperature and colorants in polymer Petrochemical Chlorination of hydrocarbons Pulp and paper Mixing bleaching chemicals with pulp Diluting surfactants Chemicals Neutralization by addition of caustic Dissolving ozone Mixing of flocculants such as FeCl3 Cosmetics and detergents Saponifying greases with caustic soda Mixing miscible/dispersing immiscible reactants Neutralization of process streams Mixing of gases in front of catalytic reactors combustion PTFE Static Mixers Details: Material Of Construction Polytetrafluoroethylene Alignment Vertical, Horizontal Color White Brand DM Design Type Standard, CustomizedFAQs of PTFE Static Mixers:

Q: What material is the PTFE Static Mixer made of?

A: The PTFE Static Mixer is made of Polytetrafluoroethylene (PTFE).Q: Is the PTFE Static Mixer computerized?

A: No, the PTFE Static Mixer is not computerized.Q: What operating grade does the PTFE Static Mixer have?

A: The PTFE Static Mixer has a manual operating grade.Q: Does the PTFE Static Mixer come with a warranty?

A: Yes, the PTFE Static Mixer comes with a warranty.Q: What type of product is the PTFE Static Mixer?

A: The PTFE Static Mixer is a static mixer.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email