-

Our Products

- Static Mixer

- Chemical Storage Tank

- FRP Vessel

- FRP Tank

- Degassing System

- Self Cleaning Filters

- Cartridge Filter Housings

- Gas Scrubber

- Industrial Strainer

- PP Tanks

- Cartridge Filter

- Air Blowers

- FRP Mixed Bed vessel

- Pickling Tank

- GRP Tanks

- Micron Filter

- FRP Damper

- Activated Carbon Filter

- Industrial Equipments

- Industrial Filters

- Degasser Column

- Demineralisation Plants

- Pressure Sand Filter

- FRP Centrifugal Fans

- Absorption Tower

- Industrial Reactors

- RO Plant

- Fume Exhaust Blower

- Water Softener Plant

- Home Page

- Company Profile

- Infrastructure

- Contact Us

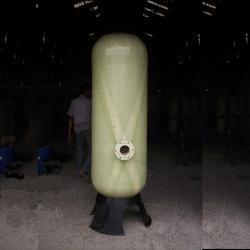

FRP Mixed Bed Vessels

10000.00 INR/Piece

Product Details:

- Application Industrial

- Type Mixed Bed Vessels

- Material FRP

- Condition New

- Color white

- Click to view more

X

FRP Mixed Bed Vessels Price And Quantity

- 10000.00 INR/Piece

- 1 Piece

FRP Mixed Bed Vessels Product Specifications

- Mixed Bed Vessels

- white

- FRP

- New

- Industrial

FRP Mixed Bed Vessels Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 5 Piece Per Week

- 1-2 Week

- All India

Product Description

FRP Mixed Bed Vessels

Enriched with vast industrial experience, we offer our clients dimensionally accurate range of Customized FRP MB Vessel. These products are durable in nature and are sturdy in construction. We offer them in varied technical grades and can be customized as per the exact preferences. We are blessed by experienced quality analyzers who keep a vigil eye on the entire production process.

Features:

- Corrosion resistant

- Light in weight

- High impact strength

- Easy to handle & install

- Maintenance free

- Superior outlook

Our USP:

- We offer customized FRP pressure vessels with hand holes for media removal & charging on bigger diameter vessels, sight glass & middle collector opening with distributor for mixed bed applications

- DME FRP vessels are available in Std. Polyester makes

- For general water treatment like filtration & softening Vinyl ester makes

- For increased regenerant/chemical resistance for DM plant & MB vessels

Engineered Excellence for Industrial Water Purification

Our FRP Mixed Bed Vessels combine high-performance ion exchange technology with durable FRP construction to provide consistent, high-quality water purification. Designed for industrial use, these vessels withstand harsh operating conditions and deliver reliable operation over an extended service life. Their non-corrosive nature ensures minimal maintenance, making them an efficient choice for a variety of water treatment processes.

Trusted Exporter, Manufacturer, and Supplier in India

As a reputable exporter, manufacturer, and supplier based in India, we adhere to strict quality standards in every FRP Mixed Bed Vessel that leaves our facility. Our expert team works closely with clients across various industries to provide customized solutions, prompt delivery, and comprehensive support, ensuring optimum performance and customer satisfaction every time.

FAQs of FRP Mixed Bed Vessels:

Q: How do FRP Mixed Bed Vessels function in industrial water treatment?

A: FRP Mixed Bed Vessels operate using ion exchange resins that effectively remove various dissolved ions from process water. This results in highly purified water suitable for sensitive industrial operations, such as electronics manufacturing or pharmaceuticals.Q: What benefits do FRP Mixed Bed Vessels offer compared to traditional metal tanks?

A: FRP vessels are corrosion-resistant, ensuring longer service life and reduced maintenance compared to metal tanks. They are also lightweight, easy to handle, and do not react with water or exchange materials, making them ideal for industrial environments.Q: When should industries opt for mixed bed vessels for water purification?

A: Industries should use mixed bed vessels when they require ultra-pure water, typically after primary treatment steps like softening and demineralization. These vessels are best suited for final polishing stages to achieve the highest purity standards.Q: Where are FRP Mixed Bed Vessels commonly installed?

A: These vessels are commonly installed in various industrial sectors across India, such as power plants, chemical manufacturing, pharmaceuticals, and laboratories, where high-purity water is essential for process efficiency and equipment longevity.Q: What is the standard process for operating FRP Mixed Bed Vessels?

A: The process involves channeling pre-treated water through the mixed bed vessel, where specialized resins exchange ions to remove remaining impurities. Regular resin regeneration and vessel inspections ensure continuous, optimal operation.Q: How can a client benefit from working with an Indian exporter and manufacturer?

A: Clients gain access to high-quality, competitively-priced vessels, customized to their needs, along with expert technical support and timely delivery. Working with an Indian exporter ensures compliance with international standards while benefiting from local manufacturing expertise and service.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email